Improve Reliability and Reduce Cost

Application: Improving reliability by replacing wire harnesses in medical diagnostic instruments.

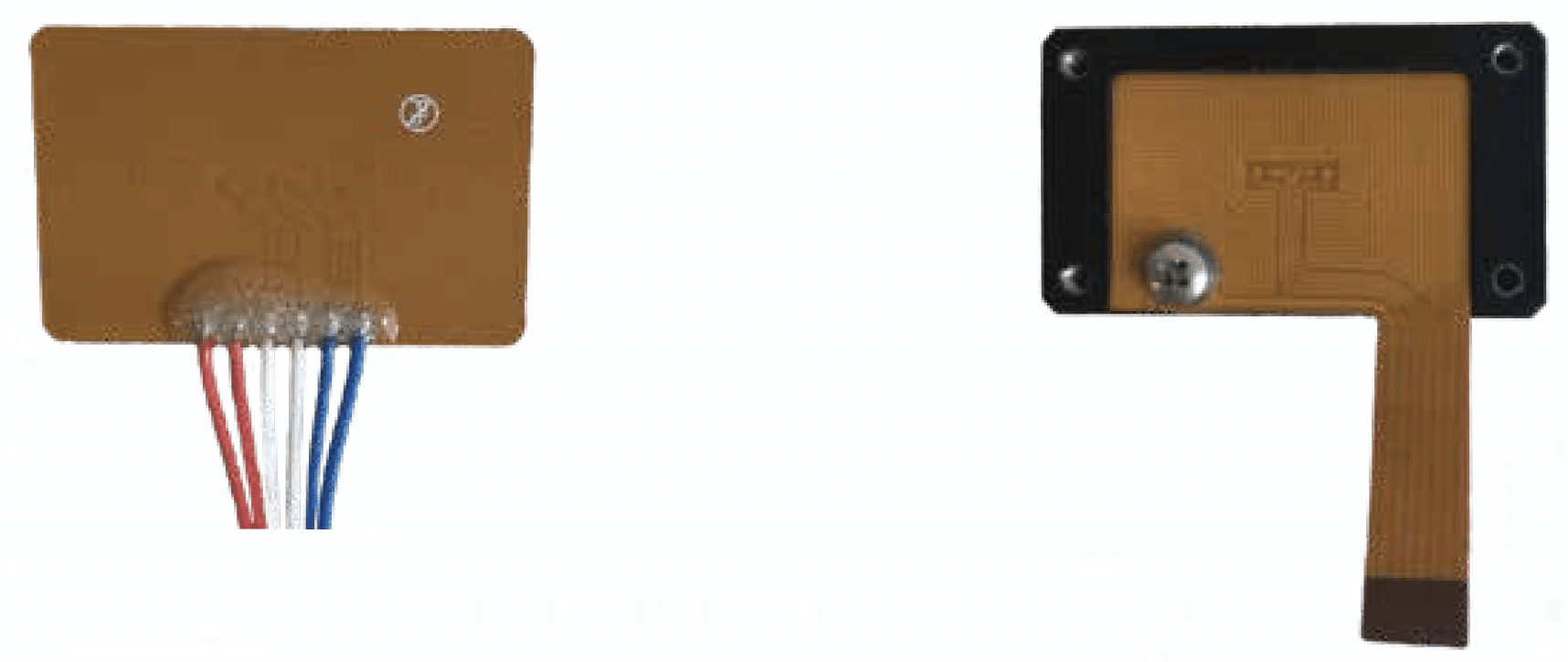

Most heater designs have a need for multiple conductors, typically two for the heater element and two for integrated temperature sensors. All Flex was given the task of redesigning a heater that was being used in a medical diagnostic instrument. The goal was to reduce the amount of interconnects, reduce cost, and increase reliability.

By switching from a conventional wire harness to a flex lead All Flex’s Design Engineers increased the reliability of the connection and reduced the amount of space and weight of the heater. While All Flex’s polyimide-based heaters already increase space savings, the elimination of wire interconnects can also make a significant impact. By using a flex lead the cost of parts and production is also decreased substantially.

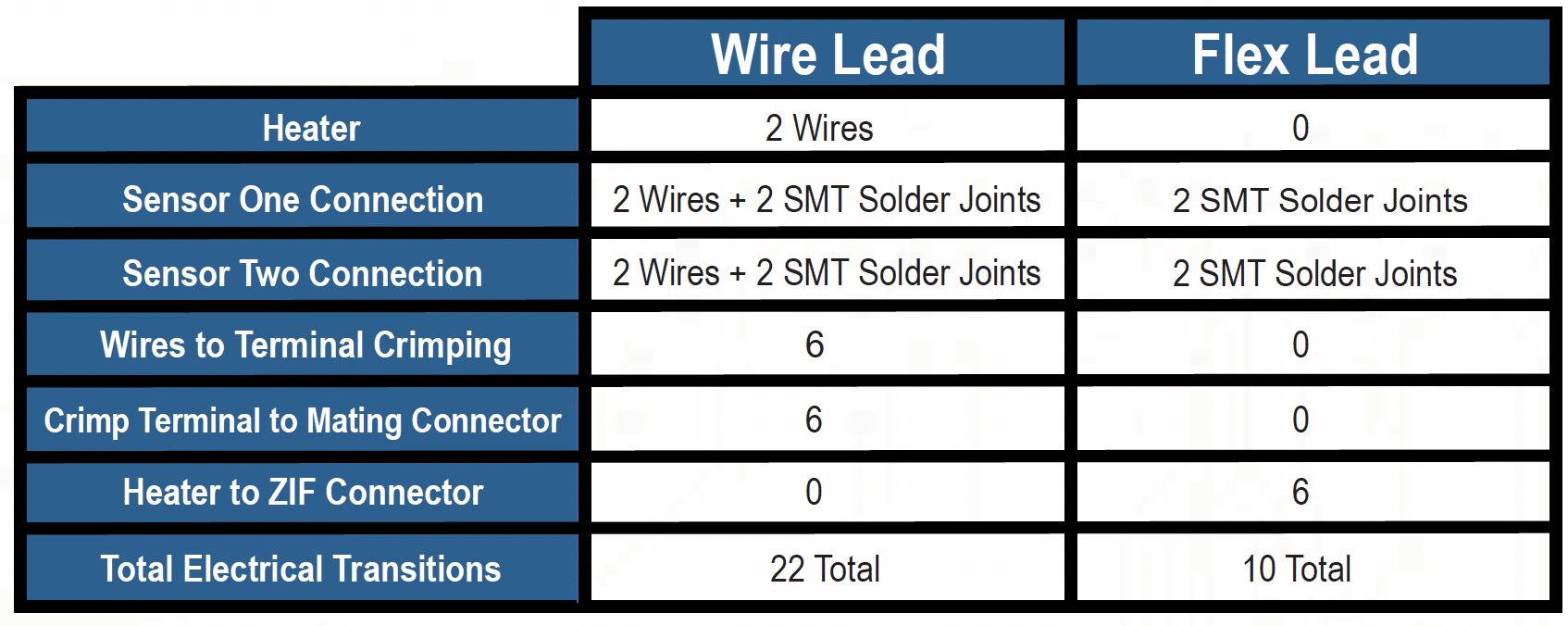

Specific improvements included:

- Reduced weight by 75%

- Reduced total cost by 70% by eliminating connector(s)

- Increased reliability by 70%

- Decreased area needed by 75%

In the example below the wired version of this heater has 22 connections, creating 22 possible locations for failure. Whereas the flex lead version has only 10 connections, a reduction of almost 55%.

Click Here to Download the All Flex Case Study – Flex Leads