CLICK HERE FOR THE FULL ARTICLE

High Temperature Control with Reduced Profile Thermocouple

Application: Creating a high temperature heater solution for cylindrical surface mounting.

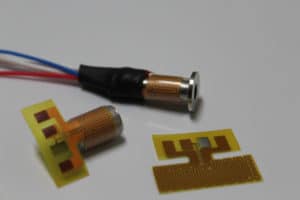

Most of the heater designs that All Flex receives are unique and customized to a customer’s specific needs. Recently All Flex encountered a new challenge, a customer wanted to control their heater above 260C, have a temperature sensor, and have an extremely thin profile. This heater would then be wrapped around and heat up a metal cylinder. Typical surface mount components would not work because of the temperature need and these components are not designed to conform to a curved surface. The solution, an etched type T thermocouple. This innovative solution has an extremely low profile and allows for the flexible heater to be placed around the cylinder without compromising reliability or performance.

customer wanted to control their heater above 260C, have a temperature sensor, and have an extremely thin profile. This heater would then be wrapped around and heat up a metal cylinder. Typical surface mount components would not work because of the temperature need and these components are not designed to conform to a curved surface. The solution, an etched type T thermocouple. This innovative solution has an extremely low profile and allows for the flexible heater to be placed around the cylinder without compromising reliability or performance.

Benefits of this technology versus resistance temperature detectors (RTDs) or thermistors are:

● Increased reliability due to elimination of solder joints

● Thinner profile

● Lower mass for airborne applications

● Up to 300C continuous temperature operation

Some novel concepts with this technology are:

● Add multiple thermocouples in series to increase sensitivity

● Combine with flexible circuits for measurement of IC’s for over temperature protection

● Integrate with maxi-flex for sensing in catheter applications