CUSTOMIZATION

With 25 years of experience designing and building custom flexible interconnect solutions, we have continually improved the design and operational processes needed for custom fabrication of 1 or 10,000 heaters. We typically release designs into production within 72 hours after receiving the order and complete the job under tight procedural controls for quality management, professional MRP-driven lots, and ISO compliance.

Our company is AS9100\ISO9001 Certified, ITAR Registered and is certified to MIL-50884, yet we run commercial products through these same business systems without impacting cost or turn time in order to be nationally competitive.

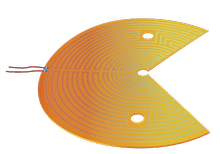

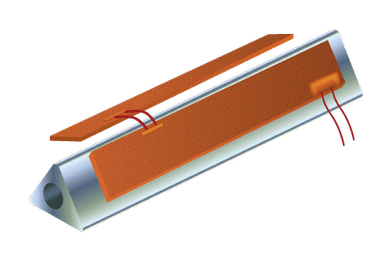

ASSEMBLY OF HEATERS

Customization not only includes unique heater designs and constructions, but it also involves integrating components and managing assembly of heaters if customers desire. We routinely assemble components onto our flexible products using automated assembly equipment or by manually soldering under magnification.

We assemble the heaters onto substrates, heat sinks, or mounting devices, saving the customer the effort of sourcing these components and dealing with the sub-assembly process.